China Seawater Uranium Extraction Technology Innovation Alliance Council launched.

China plans to have a fully operational facility capable of extracting uranium from the ocean in about a decade’s time, according to the country’s nuclear authorities.

The technical details of how China plans to build the extraction plant have not been disclosed but researchers around the world have made significant progress in bringing the idea closer to reality.

The official timeline set the date for commercial production at 2050, with a demonstration plant due to start production no later than 2035. Construction work could start as early as 2026.

The efficiency of uranium absorption materials, for instance, has increased more than 30-fold since the 1960s, according to a recent study by researchers at Tsinghua University.

“Development of seawater uranium extraction technology is expected to become a guarantee of uranium resources for the future development of nuclear energy,” said professor Ye Gang and colleagues at the Institute of Nuclear and New Energy Technology in the study published in the Journal of Tsinghua University in March.

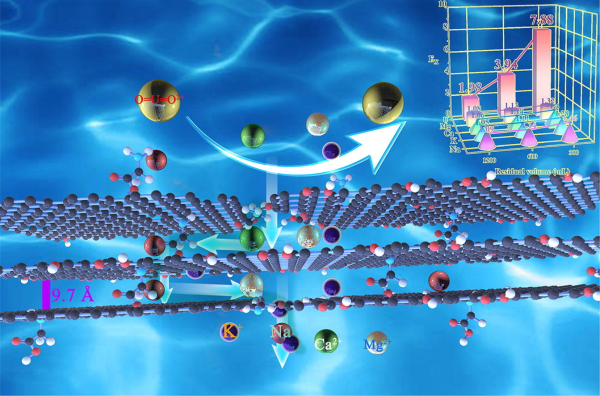

Seawater is rich in uranium, and the technology of extracting uranium from seawater has the potential to guarantee uranium resources. The uranium content in seawater is about 4.5 billion tons, which is nearly 1000 times the proven uranium reserves on land. Therefore, exploring unconventional uranium resources is expected to one of China’s strategic choices.

On 29 April 2021, the inaugural meeting of the China Seawater Uranium Extraction Technology Innovation Alliance Council was held. The alliance is led by China National Nuclear Corporation, in conjunction with the China Uranium Industry, and China National Nuclear Mining Technology.

The technology for extracting uranium from seawater is moving towards commercialisation, and the development of a sustainable national nuclear energy industry is part of China’s long-term energy security strategy.

China has set a goal to be carbon neutral by 2060 and in recent months has accelerated the approval process for building new nuclear power plants, as well as increasing its renewable energy generation capacity, as part of efforts to strengthen energy security.

More than 70 per cent of China’s uranium supply comes from mines overseas, the largest of which are in Canada and Australia – both strong allies of the US and opposed to China’s development. China has turned to its neighbours in Central Asia for natural uranium, but whether these relatively small mines can meet China’s demand appears unlikely.

Uranium in seawater exists only in trace amounts. The radioactive element also binds with oxygen and carbon in a fairly stable form that does not interact easily with other chemicals, making the extraction of uranium extremely difficult.

Scientists in China and other countries have come up with various solutions. The most hopeful absorbing material at present is amidoxime, a chemical compound that can capture the floating uranium particles. To improve its efficiency, scientists used amidoxime with other materials, from rare earths to proteins that can strengthen the bond.

The current cost to extract 1kg of uranium from the ocean costs over US$1,000 – more than 10 times the price to extract it from land, according to an estimate by Tsinghua University researchers.

However, the experience with solar technology shows that prices of alternative energy technologies can drop dramatically once proven feasible.

A researcher with the Shanghai Institute of Applied Physics, Chinese Academy of Sciences said China’s bet on developing the extraction technology was not limited to uranium. The research could also be applied in other fields, like medicine and defence.

“This is material science at the finest level. This can lead to the development of disruptive technology that can go well beyond the application in the nuclear sector,” said a researcher involved in the project.

Sources:

- Seetao Engineering Construction News, 30 April 2021

- South China Morning Post, 13 May 2021

Leave a Reply

You must be logged in to post a comment.